Category

2021 All New Design Automatic Steel Tile Aluminum Corrugated/Ibr/Trapezoidal Composite Panel Production Lines Making Machine

Overview IBR metal roll forming machine zinc color steel tile roofing sheet machines China machinery IBR is widely used

Overview

IBR is widely used in the roofing industry and a common product used in roofing applications from industrial,commercial to residential applications.It has become a household name in the South African building industry. The IBR's deep, broad flute design offers first-rate drainage abilities with ideal weight versus load/span characteristics. IBR can be factory Cranked, Curved and Bullnosed to various radii depending on customer's requirements.Because of price pressure of the material used to manufacture, this product is getting thinner and harder requiring these IBR Rollforming machines to be specially designed to produce and ensure a good quality finished product. It can also be noted that the machines are often required to run 915mm material as well or even 1225mm wide coil.

Basic Info.

| Model NO. | ibr |

| Usage | Roof, Wall, Floor |

| Transmission Method | Hydraulic Pressure |

| Dimension | 7500X1500X1910mm |

| Voltage | 380V 3phase 50Hz |

| Thickness of Material | 0.3-0.8mm |

| Material of Cutting | Cr12 Mould Steel with Quenched Treatment |

| Workers | 1-2 Only |

| Material of Roller | High Grade 45# Forged Steel Plated with Hard Chrom |

| Main Frame | 350h |

| Weight | 6.5t |

| Power | 9kw |

| Coil Thickness | 0.3-0.8mm |

| D.Shaft | 80mm |

| Speed | 12m/Min |

| Transport Package | Container |

| Specification | 40ft |

| Trademark | GEIT-ZTRFM |

| Origin | China |

| HS Code | 8455221000 |

| Production Capacity | 200sets/Year |

Product Description

IBR metal roll forming machine zinc color steel tile roofing sheet machines China machinery

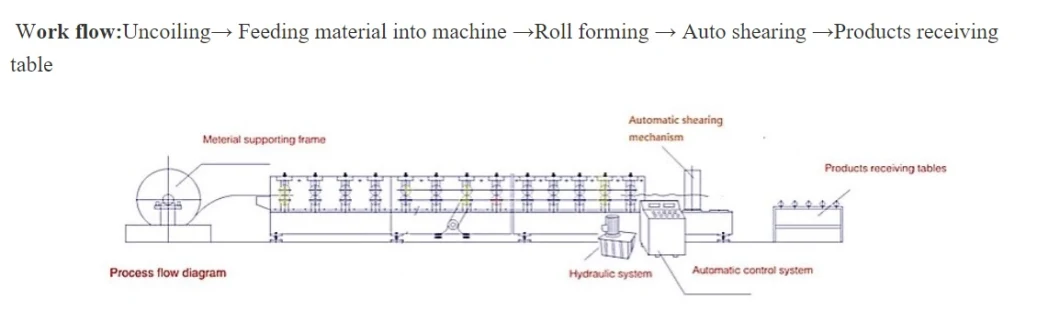

IBR is widely used in the roofing industry and a common product used in roofing applications from industrial,commercial to residential applications.It has become a household name in the South African building industry. The IBR's deep, broad flute design offers first-rate drainage abilities with ideal weight versus load/span characteristics. IBR can be factory Cranked, Curved and Bullnosed to various radii depending on customer's requirements.Because of price pressure of the material used to manufacture, this product is getting thinner and harder requiring these IBR Rollforming machines to be specially designed to produce and ensure a good quality finished product. It can also be noted that the machines are often required to run 915mm material as well or even 1225mm wide coil.

Product Parameters

| No. | IBR roll forming machine | |

| 1 | Suitable material | Color steel sheet ,galvanized steel sheet, aluminium sheet |

| 2 | Width of material | 1000mm or as need |

| 3 | Thickness of material | 0.3-0.8mm or as your needs |

| 4 | Working speed | 10-20m/min |

| 5 | Electrical control system | PLC control system |

| 6 | Shaft diameter | 80mm/85mm |

| 7 | Dimension | 7500x1500x1910mm |

| 8 | Weight | About 7 T |

| 9 | Voltage | 380V 3phase 50HZ or as the customer's requirements |

| 10 | Material of roller | High grade 45# forged steel plated with hard chrome plating |

| 11 | Material of cutting | Cr12 mould steel with quenched treatment |

| 12 | Working time | Can be 24 hours |

| 13 | Workers | 1-2 only |

Product Description

Detailed Photos

Certifications

Packaging & Shipping

Company Profile

GEIT GROUP is a professional manufacturer and exporter which is concerned with the design, development and production of cold roll forming machines.The factory located in Botou-Hebei, which focus on designing and manufacturing of different types cold roll forming machines.