Category

CO2 Foaming PS Baseboard Extrusion Line/Skirting Production Line

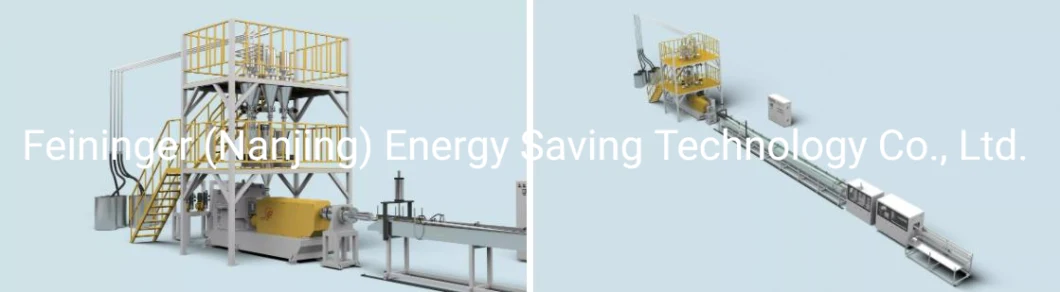

Overview Product Description CO2 Foaming PS Baseboard Extrusion LineThis PS baseboard extrusion line for floor skirting

Overview

CO2 Foaming PS Baseboard Extrusion LineThis PS baseboard extrusion line for floor skirting baseboard covering panel mainly produce PS picture/photo frames, PS moulding, Mirror frame, skirting line, floor board, ceiling corner , wall panel etc for indoor and outdoor decoration.

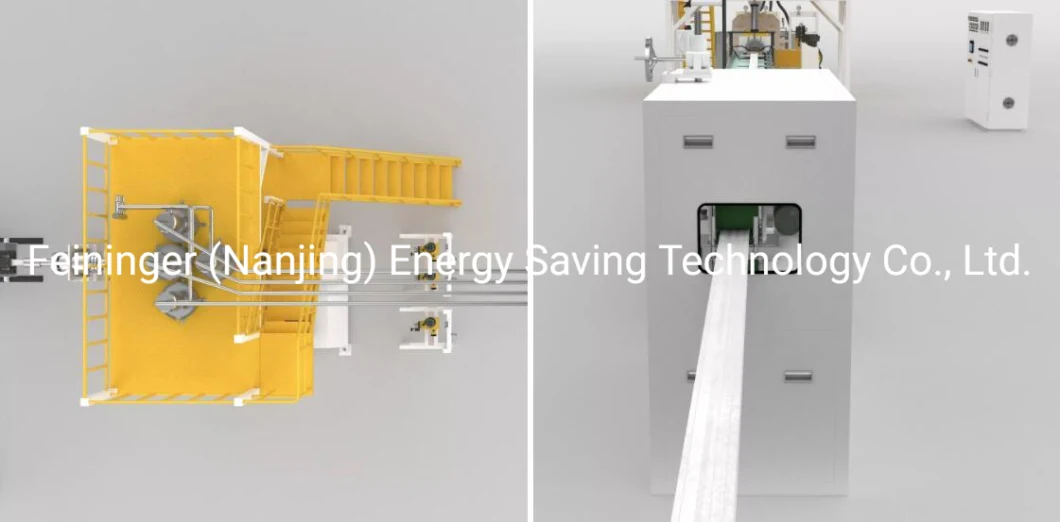

Production Process

1. Add the raw materials to be processed in a certain proportion and pour it into the mixer.2. After regular mixing and homogenizing, they are transported to a quantitative feeder bin by a feeder.3. The feeder is evenly fed to the outlet of the main extruder according to the addition amount set by the customer.4. The raw material is conveyed to the heat exchanger by the high-temperature screw of the main engine, and the heat ishomogenized.5. Then the material is conveyed to the extrusion equipment after the die, in which carbon dioxide foaming agent is injected quantitatively.6. The material model of high-temperature products made by mould is formed after cooling into a two-stage shaping jacket.7. Then the material is cooled through a water channel.8. The products are drawn to a tractor and cut with a fixed length.9. Finally, it is formed into a qualified product and packaged and sold.

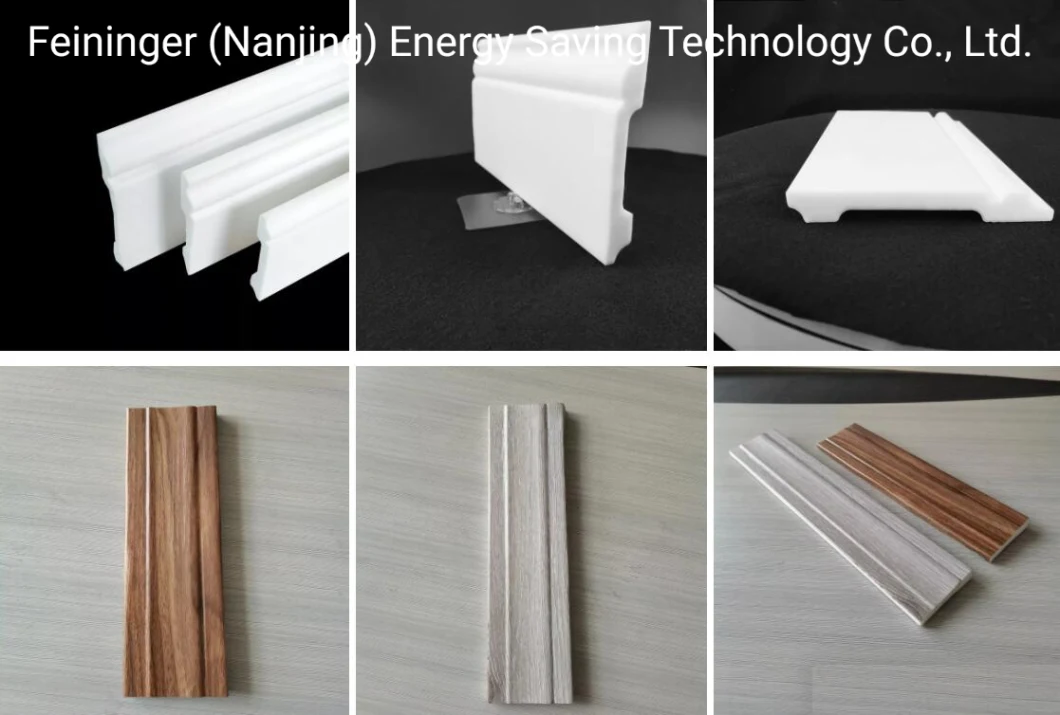

Final Product

With our PS skirting board extrusion machine, you can manufacture polystyrene cornice moulding, PS photo frame, PS baseboard, etc.

Successful Cases

Company ProfileFAQ

Question 2.

How many people need for the whole production line?

2 workers needed for the whole line. Our line is automatic, including automatic feeding system! the manual process is for packing.

Question 3.

How many densign could be produce with this machine?

We have 20 standard moulds. You also could produce any densign your market required just by providing your moulds design, then we make it for you!

Question 4.

Which foaming agent (gas)could be used in this line?

100% CO2 SUPPORTED! In China, only we can do this technology!

Question 5.

What's the density of the cornice this machine produced? The normal density is 60-80KG per cubic meters.

Question 6.

What's the raw material? GPPS (General Purpose Polystyrene).

Question 7.

Whether the cornice could be anti-flaming or not? Whether the cornice could be antioxidant or not? Yes! It could be anti-flaming and antioxidant by mixed special material.

Question 8.

Do you have and supply the raw material? If not, could you find the raw material for us? Yes, we could find material supplier for you, for the whole production line, it need about 1x40GP + 1x20ft container for shipping, and we could take some material for you, about 2 to 3 Tons .

Question 9.

How about the shipping, packing and payment ? It need about 1x40GP + 1x20ft container ,standard seaworthy packing. The payment is by TT .

Basic Info.

| Certification | CE, ISO9001:2008 |

| Customized | Customized |

| Transport Package | Wooden Cases or Pallet |

| Specification | Single extruder |

| Trademark | Feininger |

| Origin | Nanjing, China |

| HS Code | 84774020 |

Product Description

Product Description

CO2 Foaming PS Baseboard Extrusion LineThis PS baseboard extrusion line for floor skirting baseboard covering panel mainly produce PS picture/photo frames, PS moulding, Mirror frame, skirting line, floor board, ceiling corner , wall panel etc for indoor and outdoor decoration.

| Model | Extruder Type | Length/Diameter | Foam output(kg/hr) | Blowing Agent(Gas) | Thickness of Profile(mm) | Width of Profile(mm) |

| CS-75T | TE75 | 22-26 | 20-80 | 100% CO2 | 5-15mm | 25-150mm |

| CS-85T | TE85 | 22-24 | 40-150 | 8-20mm | 40-220mm | |

| CS-95T | TE95 | 22-24 | 60-250 | 8-20mm | 65-300mm |

1. Add the raw materials to be processed in a certain proportion and pour it into the mixer.2. After regular mixing and homogenizing, they are transported to a quantitative feeder bin by a feeder.3. The feeder is evenly fed to the outlet of the main extruder according to the addition amount set by the customer.4. The raw material is conveyed to the heat exchanger by the high-temperature screw of the main engine, and the heat ishomogenized.5. Then the material is conveyed to the extrusion equipment after the die, in which carbon dioxide foaming agent is injected quantitatively.6. The material model of high-temperature products made by mould is formed after cooling into a two-stage shaping jacket.7. Then the material is cooled through a water channel.8. The products are drawn to a tractor and cut with a fixed length.9. Finally, it is formed into a qualified product and packaged and sold.

Final Product

1. Environment Protection + 100% Safe

Feininger PS baseboard making machines are different from traditional chemical foaming. Our baseboard extrusion line adopts supercritical CO2 physical foaming, which greatly reduces the product density and makes the product more environmentally friendly. 2. High Performance Cost RatioWith our PS skirting board extrusion machine, you can manufacture polystyrene cornice moulding, PS photo frame, PS baseboard, etc.

Successful Cases

Company ProfileFAQ

Question 1.

How many meters produce per minute of the xps cornice machine?Different densign and size, the capacity is different, for 45mm width cornice, about 15-20meters per minute, for 58mm width cornice, about 12-15 meters per minute, for 130mm width cornice, about 6-8 meters per minutes.Question 2.

How many people need for the whole production line?

2 workers needed for the whole line. Our line is automatic, including automatic feeding system! the manual process is for packing.

Question 3.

How many densign could be produce with this machine?

We have 20 standard moulds. You also could produce any densign your market required just by providing your moulds design, then we make it for you!

Question 4.

Which foaming agent (gas)could be used in this line?

100% CO2 SUPPORTED! In China, only we can do this technology!

Question 5.

What's the density of the cornice this machine produced? The normal density is 60-80KG per cubic meters.

Question 6.

What's the raw material? GPPS (General Purpose Polystyrene).

Question 7.

Whether the cornice could be anti-flaming or not? Whether the cornice could be antioxidant or not? Yes! It could be anti-flaming and antioxidant by mixed special material.

Question 8.

Do you have and supply the raw material? If not, could you find the raw material for us? Yes, we could find material supplier for you, for the whole production line, it need about 1x40GP + 1x20ft container for shipping, and we could take some material for you, about 2 to 3 Tons .

Question 9.

How about the shipping, packing and payment ? It need about 1x40GP + 1x20ft container ,standard seaworthy packing. The payment is by TT .