Pure Color 4mm PVDF Exterior Aluminum Composite Panel ACP Sheet

Basic Info.

| Model NO. | ALB-751 |

| OEM Service | Accept Your Own Design |

| Fob Price | USD 5.0-10.0/Square Meter |

| Target Market(S) | North America, Oceania, Southeast Asia, Eastern EU |

| Fob Port | Shanghai |

| Lead Time / Delivery Time | 7-20 Day(S) |

| Panel Density | 5.5kg/M2 |

| Minimum Order | 600sqm |

| Qty/20′fc | 4mm/2380sqm; 3mm/2977sqm |

| Aluminum Alloy | 1100 3003 5005 |

| Production Lines | 10 Productions Lines |

| Transport Package | Wooden Box or in Bluk |

| Specification | 1220*2440*4*0.5 |

| Trademark | alubang |

| Origin | China |

| HS Code | 76061251 |

| Production Capacity | 45000sqm/Per Day |

Product Description

Pure color 4mm PVDF Exterior Aluminum Composite Panel ACP Sheet

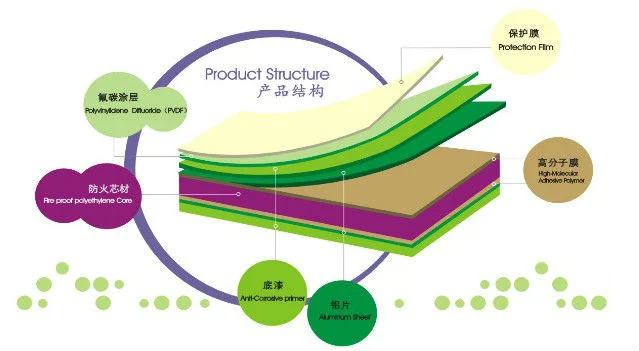

1)Material:

A) Front : aluminium alloy sheet coated fluoro-carbon resin (PVDF) with Nano lacquer

B) Core: nontox low density polyethylene

C) Back: aluminium alloy sheet coated with polyester resin painting

D) Surface coating thickness: 32μ±1μ

E) Aluminium alloy: 3003 H24

F) Sheet thickness: 0.3mm,0.4mm,0.5mm

2)Dimensions

A) Thickness: 3mm,4mm,6mm,8mm,10mm

B) Width: 1220mm,1250mm,1500mm,1570mm,1800mm,2000mm(max)

C) Length: 2440mm,3050mm,3200mm( max:6000mm)

D) Weight: 5.5kg/sqm baesd on 0.5/4mm thickness

E) Standard size:1220*2440mm

F) Qty/20'fcl:4mm/2380sqm; 3mm/2977sqm

G) Non-stanard size are available according to requirement

3)Standard:

A) West Europe standard ( Germany DIN Standard);

B) The EAST Europe standard ( Russian standard );

C) The commonweathlth standard (U.K BS Standard );

D) The North America ASTM standard;

4)Features:

A) Light weight,flat surface and high strength

B) Excellent heat insulation ,sound insulation,fire-resistance,acid-resistance,alkali-resistance,weatherproofness and non-resonance

C) Various uniform colors

D) Rbright ,elegan and magnificent,fit for various designs

E) Kynar 500 PVDF resin feature strong chemical resistance,unique colors can be easily maintained

5)Applications:

A) May be widly used in gallaies,exhibition,saloons,stores,offices,banks,hotels,restaurants and apartments

B) An ideal decorative materials for buildings

C) An ideal outer and inner walls

D) Kitchen cabinees,billboards,signboards,tunnels,subway,interiors

E) Cellings,eaves,galleries,balconies,partitions,interior decorations

F) Telephone tooths,vehicle bodies,yachts,industrial usage etc.

6)Alubang® ACP compared with solid aluminium: Required thickness and actual weights of panels with same rigidity

| Alubang® ACP | Aluminium | ||||

| Rigidity (E J) | Section modulus | Thickness | Weight | Thickness | Weight |

| 1250 kN cm2/m | 1.25 cm3/m | 3 mm | 4.5kg/m2 | 2.7 mm | 7.3kg/m2 |

| 2400 kN cm2/m | 1.75 cm3/m | 4 mm | 5.5kg/m2 | 3.3 mm | 8.9kg/m2 |

7)Alubang ACP Tolerance(mm) :

| Thickness | ± 0.2 |

| Width | ± 2 |

| Length | ± 4 |

| Diagonal | ± 5 |

8)Alubang ACP Physical Properties for Panel:

| Panel density | 5.5kg/m2 |

| Peel Strength | Average 7.0 N/mm |

| Tensile Strength | 52.5 Mpa |

| Flexural Strength | 100.0 Mpa |

| Shear Strength | 28.1 Mpa |

9)Physical properties for aluminium and coating:

| Aluminium alloy | 1100, 3003, 5005 |

| Pencil hardness | 2H |

| Toughness of coating | 2T |

| Elongation | 5% |

| Tensile strength | 130 Mpa |

| Temperature Resistance | -50°C to +90°C |

| Impact Strength | 50kg/cm2 , no change |

| Boiling water resistance | Boiling for 2 hrs, no change |

| Thermal Expansion | 2.4mm/m at 100°C Temp difference |

| Acid Resistance | Immersed in 2% HC1 for 24 hrs, no change |

| Alkali Resistance | Immersed in 2% NaOH for 24 hrs, no change |

| Cleaning Resistance | Cleaned 1000 times with water, no change |

| Oil Resistance | Immersed in 20# engine oil for 24 hrs, no change |

| Solvent Resistance | Cleaned 100 times with dimethylbenzene, no change |