PVC / WPC Wood Composite Crust / Celuka / Skinned Foam Board /Panel/ Sheet /Plate Extruder Plastic Making Machine for Door/ Furniture / Wall Production with CE

Basic Info.

| Model NO. | SJSZ80 |

| Assembly Structure | Integral Type Extruder |

| Screw | Twin-Screw |

| Engagement System | Full Intermeshing |

| Screw Channel Structure | Deep Screw |

| Exhaust | Exhaust |

| Automation | Automatic |

| Computerized | Computerized |

| Contactor | Schineider |

| Motor | Simens |

| Inverter | ABB |

| Temperature Control | Omron |

| Voltage | 380V 50Hz 3pH or Customized |

| Service | 24/7 Service |

| Certification | CE |

| Delivery Time | 30-45 Days |

| Transport Package | PVC Film or Wooden Case |

| Specification | 50m |

| Trademark | JKS |

| Origin | China |

| HS Code | 8477209000 |

| Production Capacity | 100 Lines/ Year |

Product Description

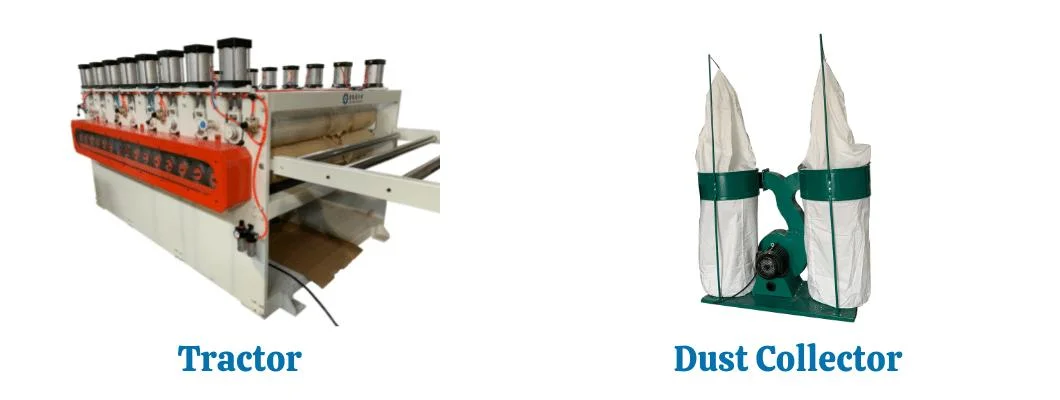

Product DescriptionThe application can be used as decoration board for kitchen cabinet, Furniture board, bathroom board, building template, construction board, WPC indoor flooring base, Advertisement board, etc.

| Extruder Model | Motor Power (KW) | Suitable Material | Final Plate Thickness | Final Plate Width | Output (kg/hr) |

| SJSZ 80/156 | 75 KW | PVC+CaCo3 | 1-12 mm | 1220mm | 400-500 |

| SJSZ 80/156 with SJSZ 65/132 Co-extrusion | 75 KW+ 37KW | PVC+CaCo3 | 1-12 mm | 1220mm | 500-600 |

Certifications

JKS Machinery Company's predecessor was the Plastic Machinery Division of Xidong Rubber Plastic Machinery Co., Ltd., established in 1970, is a professional manufacturer engaged in the development and production of plastic machinery and auxiliary equipment. Until 2013, the Plastic Machinery Division was separated from Xidong Rubber and Plastics. JKS Machinery opened its door as a plastic extrusion machine manufacturer and a turn-key plastic extrusion production line service provider in China.

With the vision and extend its competitive advantages to help customers handle plastic extrusion

Production more easily, JKS was born and soon expanded its reach to become a one-stop operational resource.

Pre-sale service:

To help customers do market research, make project planning, and production line matched requirements analysis.

After-sale service:

To provide installation and test for the machine.

To provide formulas and technology of relevant products.

To provide information on chemical material manufactories.

To provide technical training for clients' employees.

To direct technology aspect of relevant use according to customers' requirements

1. Q: Why can we make plans in one day?

A: We have more than 30 years of experience in designing and producing plastic extruders, which can help you realize your ideas quickly.

2. Q: Are you an industrial factory or a foreign trade company?

A: We are an industrial manufacturer of plastic extrusion machinery and auxiliary equipment located in Wuxi, China.

3. Q: Where is your loading port?

A: Loading port: Shanghai by sea or train.

4. Q: Payment term:

A: T/T, L/C, Western Union or cash, etc.

5. Q: Do you have other services for your products?

A: We have rich experience in manufacturing plastic machinery, so we can manufacture various machines according to customers' requirements.

6. Q: How do you quote for customers?

A: The price depends on the quality and performance, but customer satisfaction is the first priority.

7. Q: How many engineers are there?

A: We have 10 professional engineers working and they all have passports.

8. Q: What if the machine is started before delivery? Is it free or do we need to pay?

A: Of course, we have to start the machine for you to check until you are satisfied with our machine and it is free.